business

business

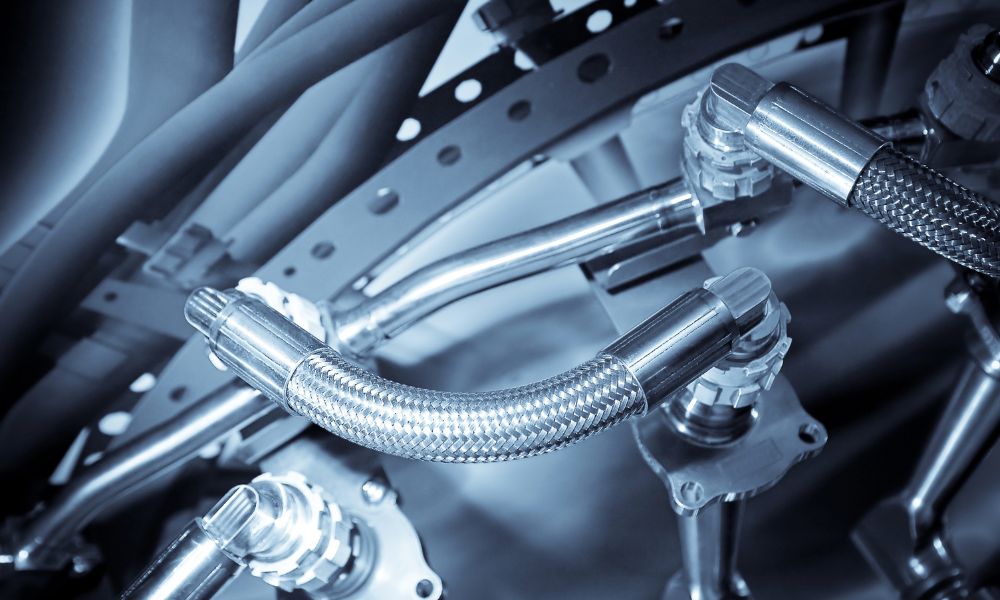

If your business or workplace has an industrial hose system, you understand that these hoses and parts aren’t cheap. Get the most value out of your industrial and hydraulic hoses by preserving them with our helpful maintenance and storage tips.

Regular and thorough visual inspections are the first steps in quality hydraulic hose maintenance. The last thing you want is for a busted or leaking hydraulic hose or fitting to catch you by surprise and cause significant issues.

The only way to stay ahead of leaks and ruptures is to conduct frequent inspections that look for things like the following:

If you spot any of these issues, you should remove and replace the affected parts as soon as possible to avoid a larger catastrophe.

Another part of inspections and maintenance for industrial hydraulic hoses should be routine functionality tests. Functionality tests include hydrostatic pressure tests that push the system beyond its maximum working pressure for a short period.

By pushing the hoses past their limits for a short time, minor leaks and ruptures become more apparent, allowing you to resolve them before they become more significant. These simple functionality tests are critical to ensuring the hydraulic hoses and fittings are working at their best.

It’s also important that hydraulic hose assembly owners and maintenance staff keep detailed maintenance logs of their visual inspections, tests, and more. Anyone on the maintenance staff should be able to open the logs and know the age of every hose and component, recent maintenance, inspection results, and more.

This simple data ensures that you can closely inspect and replace hoses and components approaching the end of their lifespan when needed and optimize downtime for maintenance and repairs.

A crucial part of preserving industrial and hydraulic hoses is ensuring that you store them carefully before using them. If you have spare hoses and assembly components, you should store them in climate-controlled, comfortable surroundings to keep them fresh and prevent them from becoming brittle and fragile.

Keeping the hoses and parts in their original shipping containers is typically best if you don’t have storage enclosures to keep out water, oil, and pests. Proper storage ensures the hoses and parts stay as fresh as possible before you introduce them to the system.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com